OUR LOCATIONS

We can provide our services to power plants worldwide

Bradenton, Florida

941 - 527 - 6196

941 - 755 - 5229 (FAX)

Milwaukee, Wisconsin

414 - 698 - 5644

|

MODELING AND

ANALYSIS

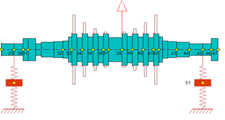

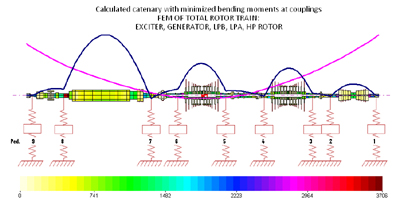

Finite Element Modeling of a turbine generator system is a crucial tool for troubleshooting certain vibration problems. Modeling is equally important for testing possible solutions, such as an adjustment in rotor train alignment or bearing position(s), catenary optimization, or for bearing redesign, or to predicatively test the behavior of replacement components, and to identify resonance frequencies.

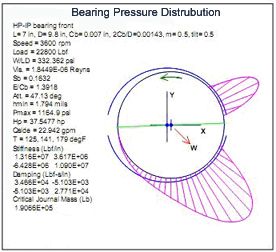

Z-R Consulting uses Rodyn (Dyrobes) finite element software to model and analyze specific rotors or a complete rotor train, including specific bearing and pedestal properties. We can readily predict and identify all mode shapes and resonances, both lateral and torsional, in the rotor train, in specific rotors, and in the rotor blades themselves. We can simulate the effects of misalignment, bows or eccentricities, bent couplings, and other problems. All bearings can also be modeled and predictively modified in detail.

Z-R Consulting uses Rodyn (Dyrobes) finite element software to model and analyze specific rotors or a complete rotor train, including specific bearing and pedestal properties. We can readily predict and identify all mode shapes and resonances, both lateral and torsional, in the rotor train, in specific rotors, and in the rotor blades themselves. We can simulate the effects of misalignment, bows or eccentricities, bent couplings, and other problems. All bearings can also be modeled and predictively modified in detail.

Our predictive finite element models have time and again proven to be highly accurate. Identifying rotor train behavior ahead of making repairs can ensure that the optimum solution is found and implemented in an efficient manner. Our models can also point to causes of past component failures.

For jobs incorporating a full or partial rotor train upgrade or replacement, Z-R Consulting can accurately model the new rotor(s), predict and verify lateral and torsional resonances, and recommend operation procedures to avoid improper holding speeds or other areas of danger. We can also provide specific alignment procedures and catenary guidelines to avoid any residual coupling moments and thereby avoid potential 2-per-rev cyclic fatigue on the turbine blades.

We are also developing a predictive rotor balancing modeling method to combine with our accurate FE models, incorporating our 2N+1 balancing concept, that could allow the complete balance solution to be found before even placing the rotor in a balancing bunker.

|